Stallion Tombstone Fixture Featuring 5th Axis Workholding

- Apr 7, 2025

- 3 min read

From time to time, or very often for some shops, a batch of parts comes through the door that not only requires multi-op machining, but also a high-volume solution. The traditional way to handle this is to design 3 or 4 special fixtures to hold this part for each operation and manually rotate the workpiece until the finished part is complete. Today, with the growing interest and market for 5-axis machines, this process can be eliminated relatively quickly, but not for an inexpensive price tag. So what does one do when presented with a high-volume job that requires multiple operations? Using a tombstone style trunnion table with flexible and repeatable workholding, high volume can be achieved in your 3-axis mill affordably and smoothly.

Today we are discussing the combination of 5th Axis Workholding products, Lyndex Nikken rotary tables, and the Stallion Tombstone fixture. Last week we put out a new animation that featured products from all three of these companies. You can view this video below for context.

We are using the Lyndex Nikken CNC 260 for this project as it has a weight capacity of 673 lbs, which is plenty to rotate our completed fixture with ease. To maximize volume, we are using a 6" Stallion tombstone fixture. This product is made from class 35 cast iron, making it a rigid solution with minimal chatter. Tombstone fixtures can be made to virtually any length and with any face size required for your workholding and workpiece. We are going to break down each piece of this fixture and discuss the role it plays in this productivity beast.

First, let's talk about the rotary table. This CNC 260 from Lyndex Nikken has a center height of 170mm, a 260mm faceplate with 8 key slots for mounting, and a weight capacity, as stated earlier, of 673 lbs. Because we decided to go with the RockLock bases, we had no choice but to include a 2.5" center height. The trunnion table fixture is located in the through hole in the faceplate of the rotary table and is mounted using t-nuts and SHCS.

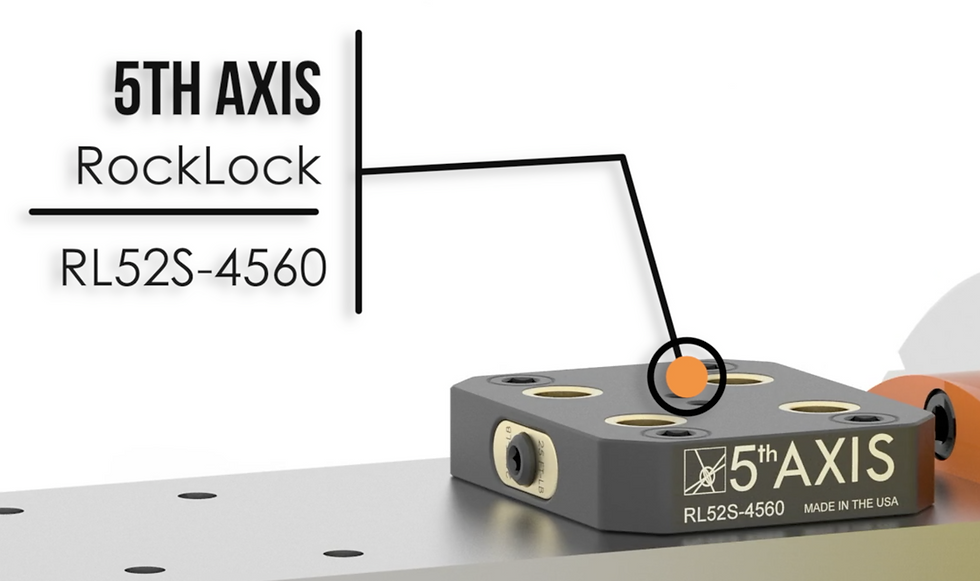

Moving on to the trunnion fixture itself, this is a 6" tombstone measuring 36" in length and, of course, features the mounting pattern for the rocklock bases from 5th Axis. This tombstone is made entirely from class 35 cast iron, making it extremely rigid and capable of absorbing vibration. These features help to eliminate chatter and flex. It also features the TS1200 hydraulic braking system, which allows for heavy, off-center milling and drilling with its 500 ft. lbs. of clamping torque. In this application, we decided to go with the RL52S-4560 RockLock bases as well as the V75100X Self-Centering Vises. These vises offer plenty of clamping range to support the workpieces.

|  |

| One of the main pros of this fixture is the ability to rotate the 5th axis vise 90 degrees to machine an additional operation. Therefore, we have two sides of the tombstone setup for the first three operations and another two setup for the final two. See photo to the left for reference. |

Combining products from Lyndex Nikken, Martin Trunnion Tables, and 5th Axis can potentially save you hundreds of thousands of dollars that would be spent on a 5-axis mill. Reach out to us today for a free consultation on improving your 3-axis mill with a complete 4th-axis workholding solution.

Comments