Automation-Ready Workholding for a FANUC RoboDrill

- Nov 5, 2025

- 2 min read

At Martin Trunnion Tables, we specialize in building workholding solutions that make machining easier, smarter, and more efficient. Our latest project? A fully integrated hydraulic automation fixture built specifically for a FANUC RoboDrill machining center — and it’s packed with features designed to eliminate part handling and boost rigidity.

A Fully Custom, Automation-Ready Setup

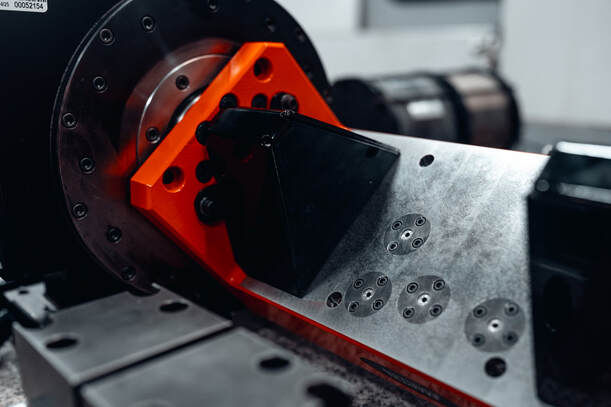

This build was developed with one goal in mind: seamless integration into a high-output automation cell. Starting with our signature one-piece cast iron trunnion, known for its extreme rigidity and vibration-dampening properties, we designed the system to support autonomous operation and full 360° rotary motion.

Key to this build is the integration with the RoboDrill’s DDR rotary table, where we installed a custom rotary union system. This setup prevents hydraulic lines from tangling during rotation — a critical consideration in automated machining environments.

Autonomous Clamping with Hydraulic Power

Since robot-loaded workholding requires autonomous actuation, we chose a SCHUNK KSH3 hydraulic vise for its consistent high clamping forces and repeatability. The vise is mounted using precision-tapped and reamed holes — but what really sets this system apart is the internal hydraulic manifold setup.

We embedded four steel manifolds inside the trunnion, allowing the vise to be oriented in either direction depending on the application. These manifolds connect through bent hard lines housed underneath the trunnion, all protected by custom sheet metal covers for chip flow and line safety.

Why four manifolds? The SCHUNK vise requires both open and close ports — and the customer wanted orientation flexibility, so we delivered both.

Engineered for Chip Control

In automation, proper chip control can make or break a system. That’s why we included sheet metal guards to guide chip flow and prevent buildup around the vise — a must for reducing downtime and avoiding robotic misfires. It’s a small detail that makes a big difference.

Built-In Rigidity with the TS1200 Hydraulic Brake

To maximize system stability during machining, we added our TS1200 hydraulic braking system to the assembly. Connected directly to the DDR’s internal brake via a vect booster and solenoid valve, the TS1200 clamps the opposite end of the trunnion in perfect sync with the rotary table. The result? Unmatched rigidity — even during heavy cutting or finishing passes.

Designed for Full Rotation

The fixture is mounted on a 1" riser block, allowing uninterrupted 360° rotation. While not every cycle requires full rotation, proper clearance is essential for homing and safe operation — especially in an automation cell.

Why It Matters

Designing for automation is not just about holding parts — it’s about eliminating unnecessary handling, increasing reliability, and integrating every component for peak efficiency. This custom trunnion package checks all the boxes for robotic machining, and we can’t wait to see it in action.

Want to automate your vertical machining center with a fixture like this? Let’s talk.

Comments